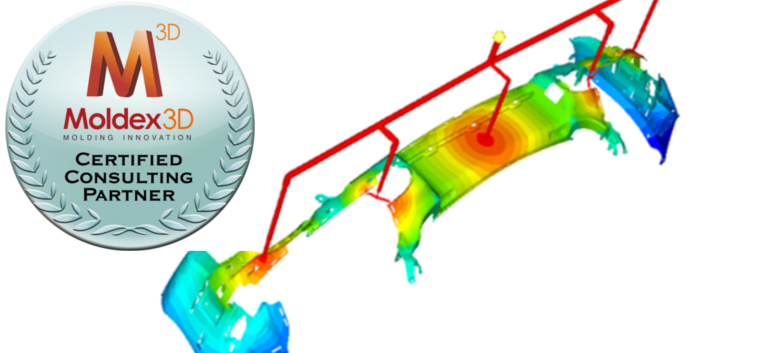

Logycad makes its knowledge in injection moulding simulation available to its partners, pledging a solution for any issue can occur.

Close collaboration with TETYS SRL, a distribution company of Moldex3D software, has consolidated our know how.

Coretech System Ltd, producer of Moldex3D software, has certificated LOGYCAD SRL “Recommended Consulting Partener“, first and only in Italy. See more.

Injection Moulding Simulation

The deep knowledge of CAE software and a twenty years-expirience in injection moulding, allows to prevent and solve the issues of the process, ensuring:

- Dimensional control: tolerances, deformation, shrinkage

- Surface quality: blemish delete

- Stress evaluation

Product Development

Develop products respecting dimensional, quality and standards requirements. Provide advice and support to optimize product and solve issues found during the production

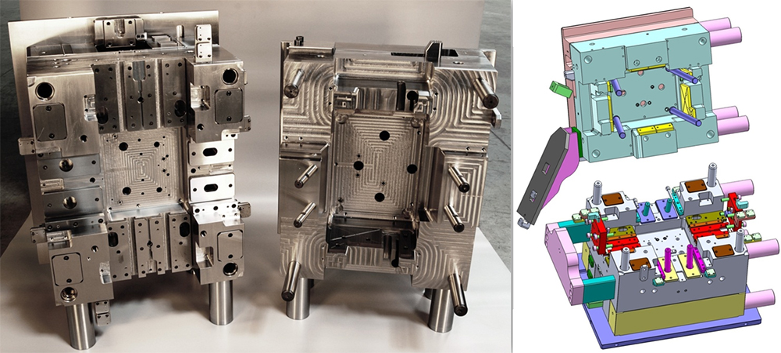

Mould

Develop and support mould design. Manage issues related to:

- Feeding (hot runner, cold runner, position and balancing)

- Conditioning (sizing, bilancing, special insert)

- Plastic material (selection, test new material)

- Mechanic (shrinkage, cavity, inserts, vents)

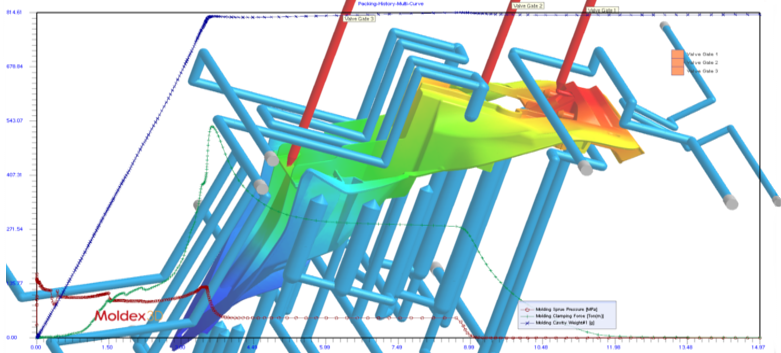

Moulding

Support the choice of components and process parameters in order to reduce issues during the production and to solve defects in the products:

- Support choice of material and press

- Optimization:

- Process parameters

- Close pressure

- Shrinkage

- Junction lineand air trap

- Surface blemish and suction mark

- Cycle time

- Costs