Logycad team gained experience within different fields of the production cycle over more twenty years. Its natural habitat is the development of projects in their entirety and complexity, from the design conception up to the production start up.

Co-design

Development Executive Design

Know-how extends to all phases of product production. Develop the whole project according to the customer constrains and specifications.

A careful analysis of the production phase, technology and costs, minimize the return of investments (ROI).

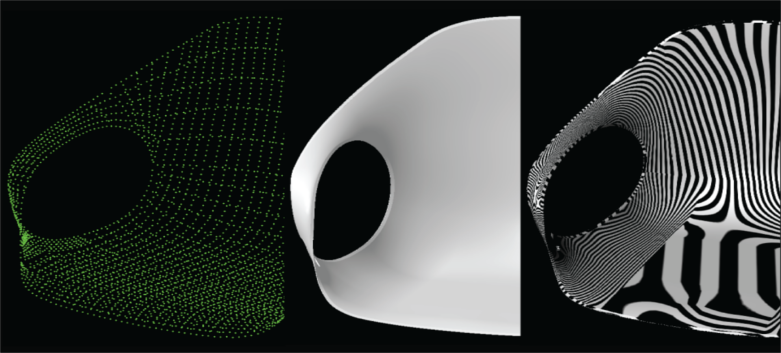

Reverse Engineering

Digitalization of physical objects through Optical Scan tools, in order to:

- Reconstruction and optimization surfaces

- Modeling and create parametric CAD

Realization Aesthetic and Functional Prototypes

Realization, thanks to long term partnership with leading companies for rapid prototyping, of aesthetic and functional prototypes with different levels of quality and complexity.

Logycad is able to realize:

HARD AND SOFT TOOLS

- Low price aesthetic prototypes

- Full aesthetic and functional prototypes

- Production small series

- SLS (Sintering Laser System)

- SLA (Stereolitography)

- MJM (Printer 3D Multijet Modeling)

- LOM (Printer LD sheet thermoplastic lamination)

- Drop on demand (chalk, starch and ceramics)

- Silicon moulds

- Low cost moulds for small production

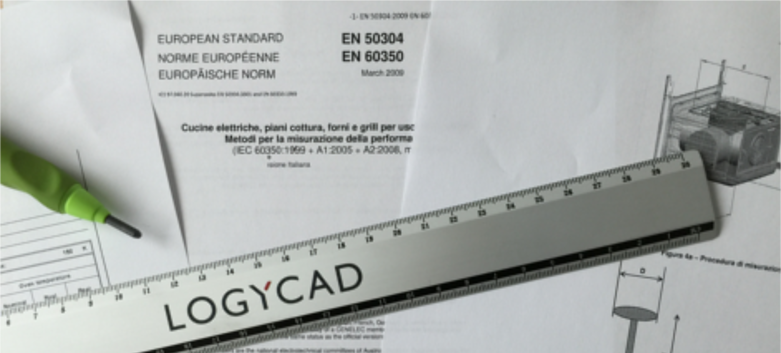

Functional and Performance Test

In compliance with the requirements LVD (Low Voltage Directive) and standards for Gas appliances:

- Respect European standards

- Compliance of Own’s book to the use of product

- Heating test (normal and anomalous working conditions)

- Reliability test

- Performance test

- Climatic and wet chamber test

- Components test

- Virtual Simulation

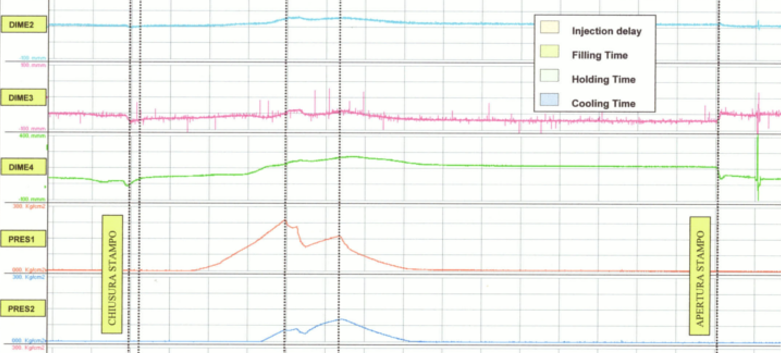

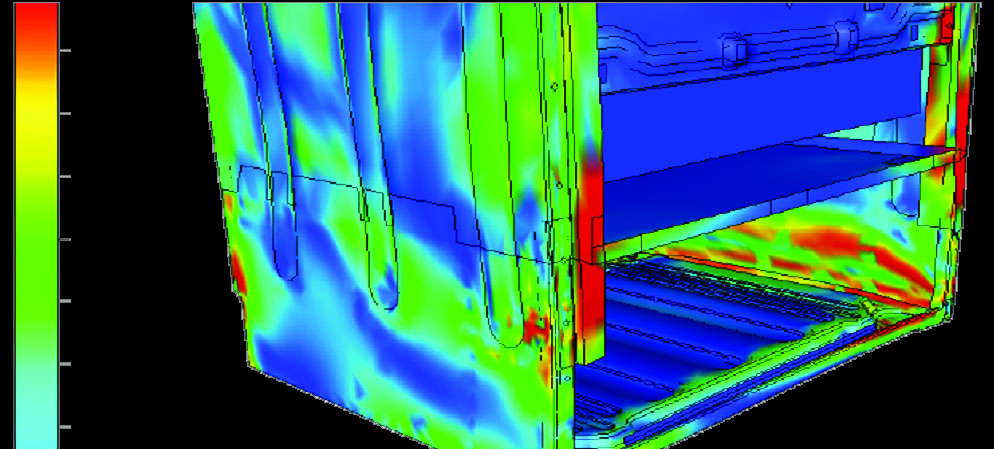

Virtual Simulation

Virtual simulation of any kinds of physical phenomenon. Forecast behavior of components during the whole life cycle and solve issues that can occour during production and use.

PLASTIC MOLDING SIMULATION See More…

STRUCTURAL ANALYSIS

- Static

- Dynamic

- Thermal

- Fluid dynamic

- Mass diffusion

- Coupled analysis

Product Certification Consulting

- CE

- SASO

- …

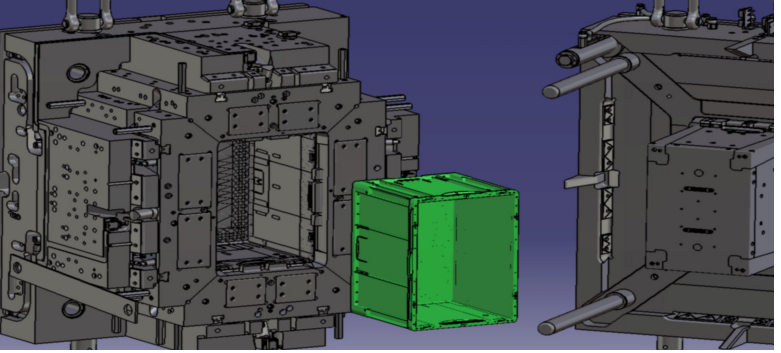

Mould Design

Mould design, ensuring solutions able to prevent unexpected

behavior during the production and avoid defects in the products.

FIELDS

- Plastic

- Sheet metal